http://japhop.blogspot.com/2010/09/project-1.html Jin YueYue

http://kangmark.blogspot.com/ Mark kang

http://allenyie.blogspot.com/2010/09/experience-enrichment.html? Allen Yie

http://stasiep.blogspot.com/ Anastasie Panagopoulos

http://mycollectionsofmisdirections.blogspot.com/ Kane Yong

Tuesday, September 28, 2010

Thursday, September 23, 2010

Redesigned Product

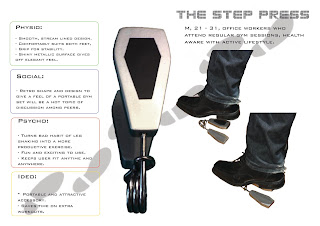

Rationale: The Step Press

The Step Press is a variation of the popular hand grips used for body and leisure workouts, but designed to be used for the calf muscle. It works by the user placing a foot on the top pedal and using the calf muscle to press down, with a torsion spring providing resistance. The target market this product is aimed at are young office working men aged between 21- 31. They are men that are health conscious and regularly work out at the gym and enjoy social outings.

The idea for this design came about when researching different work out equipment; I noticed that there weren’t many tools designed for leg workouts that could be easily accessed anytime. On occasion, people may find themselves having to work overtime, and won’t be able to make it to the gym, so the product I designed will help make up for some lost time.

During the early stages of the design, I went through many shapes to try come up with something unique that both worked and balanced. I ended up with a pedal shaped design that would comfortably fit under the feet, but also featured a simple, streamlined look that would look great on the office desk when not in use.

One of the main issues evaluated for the step press included the weight. In order for the product to be portable it had to be fairly easy to carry, so I chose materials that would make it light weight. This meant that I had to sacrifice steel pedals for plastic; however, after testing various hand grips, I determined that plastic would have enough strength to withstand the force of a leg pressing down on it.

The finalised product will feature three core pieces, consisting of the pedal, base and torsion spring. Both pedals will be made from plastic that will be injection moulded to be attached to the torsion spring. The spring will be made from chrome plated steel. The last touch will be softex material, which is a durable alternative to rubber and cheaper to produce, which will be attached to the pedal and base to act as a grip, creating a satisfying product that will be sure to get the user pumped.

Subscribe to:

Comments (Atom)